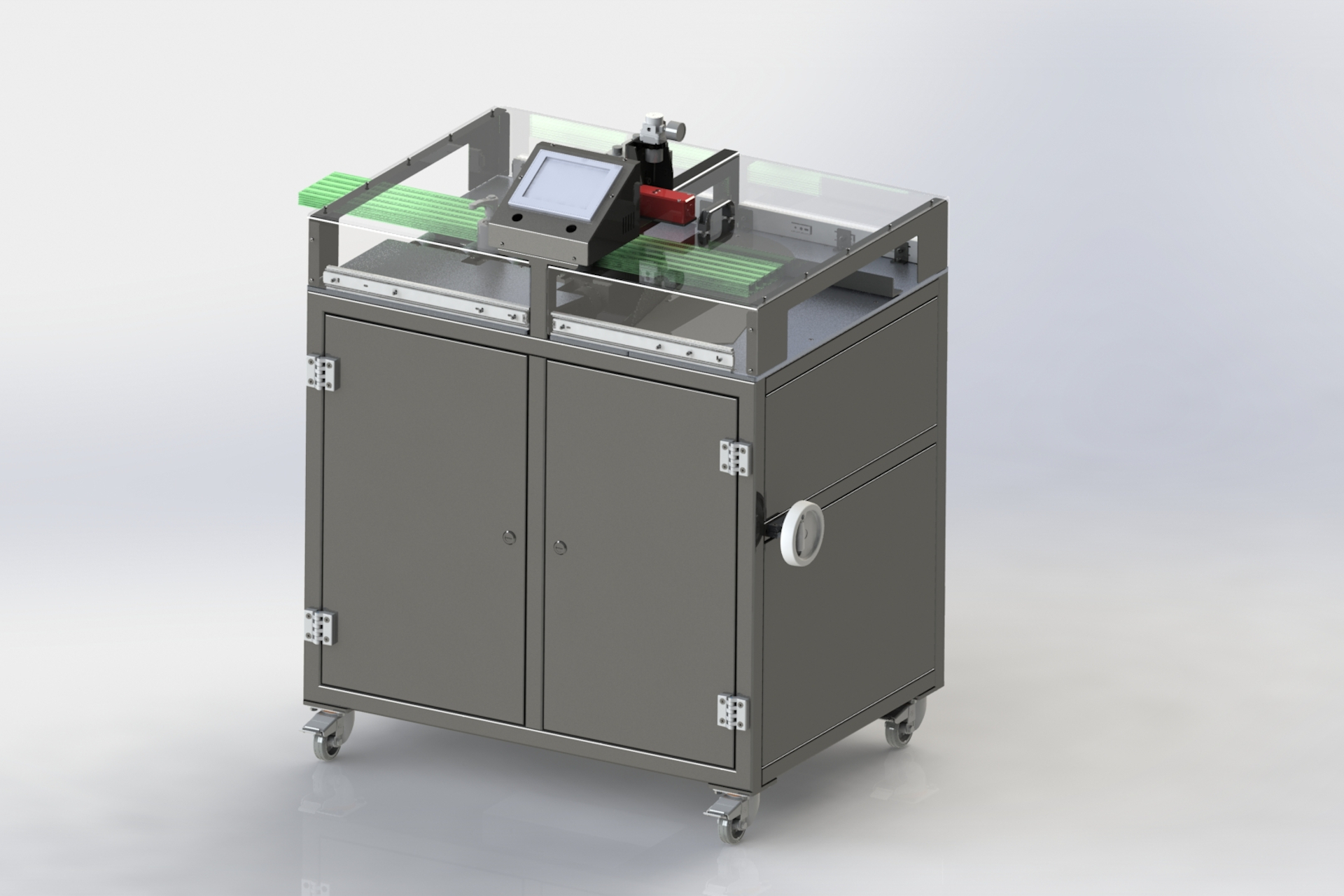

Automatic Plastic Profile Cutter

Efficient production of custom-length plastic parts - with less labor and zero waste

The Problem

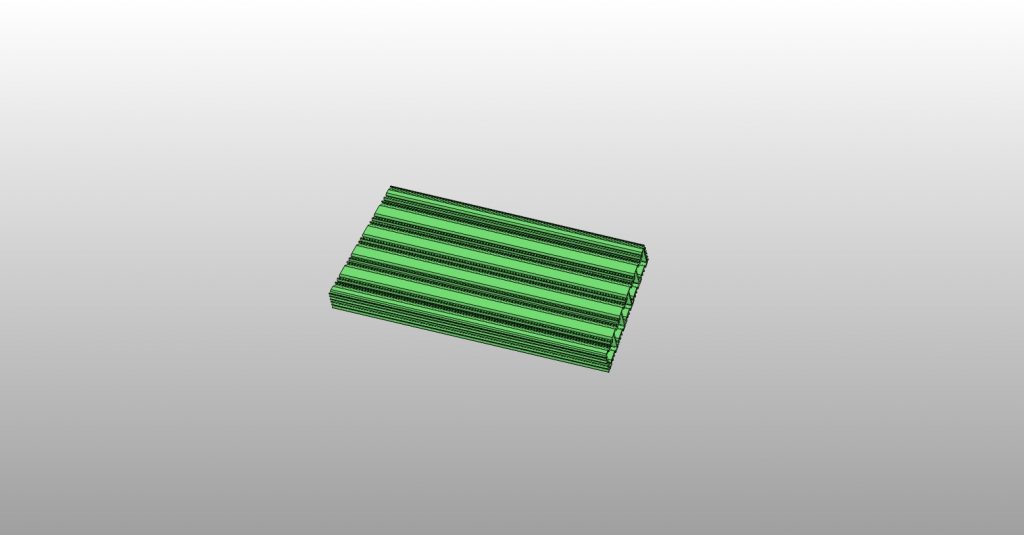

A client needed a better way to produce a specific plastic part used in his product. At first glance, the part was simple — a plastic block with a rectangular cross-section and two sides angled by 3-4 degrees. However, the tricky part was this: the length needed to be variable, so the part could fit inside other plastic components of different widths.

The client initially tried injection molding the part and cutting it to size before assembly. This turned into a frustrating, wasteful process:

The Solution

We approached the problem from three angles — part redesign, production method, and custom automation.

The Result

The client saw immediate and long-term benefits:

Facing a similar production challenge?

We design and build machines and tools that solve real manufacturing problems — fast, affordable, and built for small manufacturers.

Let’s talk — your first consultation is free.