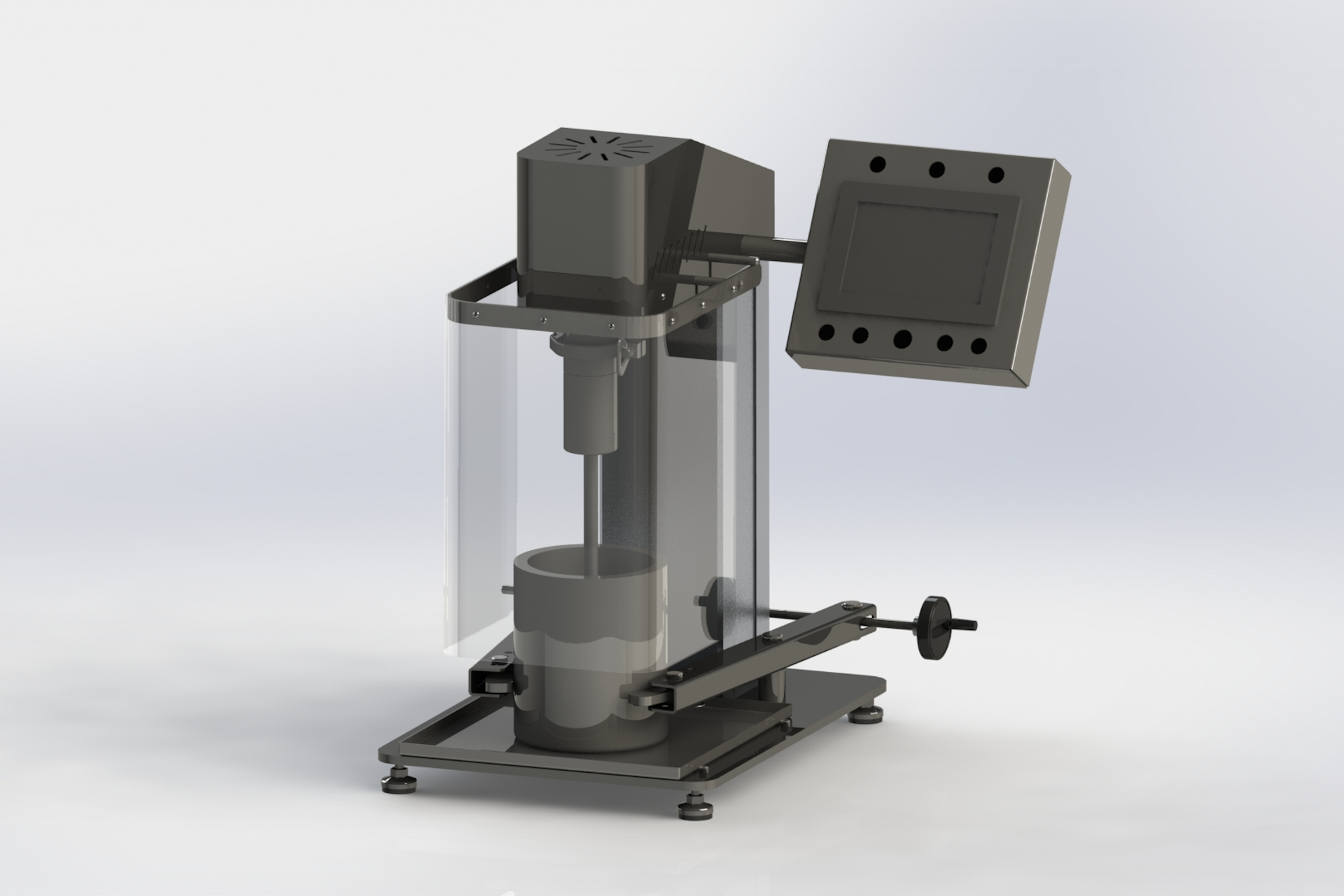

Lab mixer

Superior product quality with vacuum mixing. The way to eliminate air from a liquid product.

The challenge

Our client, a specialized manufacturer of waterproofing compounds, faced a challenge common in the production of liquid and semi-liquid products. Their batches occasionally suffered from issues directly linked to the mixing process. Traditional open-air mixing introduced trapped air into the compounds.

This wasn't just an aesthetic concern; it had tangible impacts:

Suboptimal Product Performance: Air pockets could compromise the integrity and long-term durability of the waterproofing barrier, potentially leading to customer dissatisfaction or performance issues in critical applications.

Inconsistent Batch Quality: Achieving uniform, air-free consistency across every batch was a struggle, sometimes leading to material waste.

Efficiency Bottlenecks: Manual checks for air bubbles and the risk of discarded batches impacted overall production efficiency and labor allocation.

The client needed a solution that would eliminate these mixing-related defects, and verify mixing parameters and ingredients ratio for larger scale production.

The Solution: Vacuum Mixing Technology

To address these issues, we collaborated with the client to design and develop a lab mixer with an interesting capability: mixing under vacuum. This innovative approach directly targeted the root cause of the problem – the introduction of air during mixing.

Key features and benefits of the custom-designed solution included:

Mixing In Vacuum: The mixer was engineered to operate and maintain a vacuum inside the mixing vessel, actively removing air during the entire mixing cycle. This ensures the integrity of sensitive compounds from start to finish.

Electronic Controls: Equipped with integrated electronics, the mixer allows for precise speed control and timed mixing cycles. Operators can simply input the desired parameters, guaranteeing consistent and repeatable results.

Versatile and Adaptable Design: Recognizing the need for flexibility, the mixer features changeable mixing attachments, allowing the client to select the optimal impeller for various compound viscosities and formulations.

Furthermore, the design is inherently scalable, with the ability to build units ranging from the initial 2-liter capacity to much larger volumes, or even smaller, precisely matching future production needs. Robust & Hygienic Construction: The entire unit is fabricated from stainless steel, ensuring exceptional durability, chemical resistance, and ease of cleaning—critical for maintaining product purity and extending equipment lifespan.

Enhanced Safety: A clear polycarbonate shield provides a crucial physical barrier between the operator and the mixing pot, prioritizing safety during operation. The design also holds a CE certificate, affirming its compliance with European safety standards.

The Result

The implementation of the custom vacuum lab mixer yielded significant and tangible results for the waterproofing compound manufacturer:

Unprecedented Product Quality: The most significant outcome was the dramatic improvement in the quality of the waterproofing compounds. With the elimination of trapped air, the final product demonstrated enhanced consistency, improved application properties, and superior long-term performance, directly leading to a higher-quality end product for their customers.

Reduced Waste: Batches that previously might have been compromised by air bubbles or inconsistencies were now consistently perfect. This led to a significant reduction in material waste.

Scalability for Future Growth: With a proven design in place, the client now has a clear pathway for growth. Whether they need to scale up to larger batches or develop new, sensitive formulations, the customizability of the mixer design ensures their equipment can evolve with their business.

Ready to Optimize Your Manufacturing Process?

Do you face unique production challenges that off-the-shelf machinery can't solve? Our expertise lies in designing innovative, practical, and high-performance machines tailored precisely to your unique manufacturing needs.

Let's discuss how a custom-engineered solution can transform your business, enhance product quality, and drive efficiency.

Contact us today for a free consultation and let us optimize your production process.